technology

Certification Of Industrial Agency

JUNGANG-ENG can produce pressure vessels and heat exchangers based on the relevant domestic regulations.

Pressure Vessel

Pressure Vessel

Safety Certificate

| Machinery / Equipment | Scope | ||

|---|---|---|---|

| Machinery / Equipment | Pressure Vessel | Scope |

Fluid handling vessels in chemical processes or vessels (gar or nitrogen handling vessel) used in other processes for which gauged design pressure exceeds 0.2MPa(2kgf per cm3); vessels falling under any of the following categories are excluded.

|

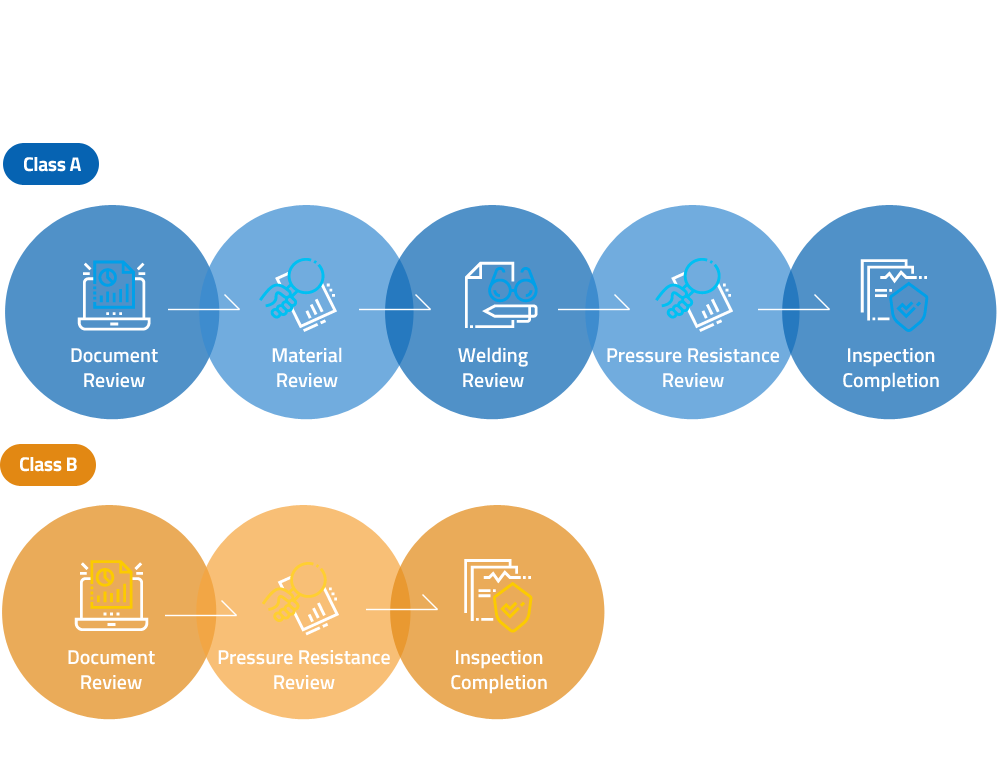

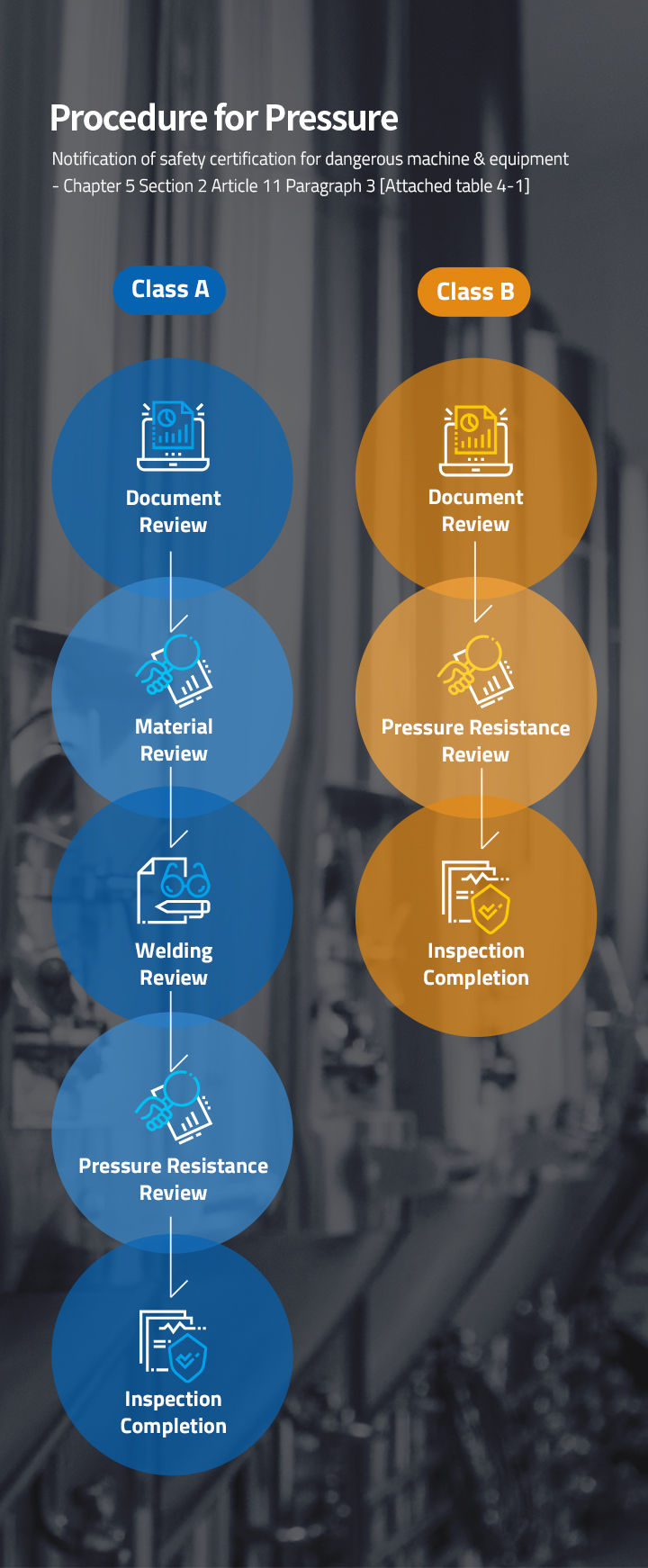

Notification of report procedure for safety certificate and voluntary safety certification- Article 2, Chapter 1 [Attached table 1]

| Type | Item Name | Scope | |

|---|---|---|---|

| Type | Pressure Vessel | Class A |

What is a class A pressure vessel?

A fluid handling vessel with a gauged design pressure that exceeds 0.2MPa(2kpf/cm²), and a gas or nitrogen handling vessel with a gauged design pressure that exceeds 1MPa(10kgf/cm2) |

| Class B | Vessels other than class A pressure vessel |

* Notification of safety certification for dangerous machine & equipment - Chapter 5 Section 1 Article 10 Paragraph 2

Safety Inspection

Inspection to check installation status after installing machinery or equipment subject to manufacturing inspection

Subject to inspection

Article 78 (1) of the Enforcement Decree Of The Occupational Safety And Health Act, Article 3 of the notification of safety inspection procedure [Attached table 1]

Fluid handling vessels in chemical processes or vessels (gar or nitrogen handling vessel) used in other processes with a gauged design pressure exceeds 0.2MPa(2kpf/cm²); vessels falling under any of the following categories are excluded.

- Vessels whose internal diameter, width, height, or section diagonal length is 150mm or less (nominal diameter 150A if using pipes), regardless of vessel length or pressure

- Nuclear vessels

- Water cooled tubular condensers

(limited to cases where coolant is flowing in the body side, and observed working pressure is lower than working pressure in the body side) - Vessels that handle water with a service temperature lower than 60° only

(additives in the water are allowed if the flashpoint of water base solution is 35° or higher under air pressure) - Plate type heat exchange

- Fin type air cooler

- Explanation about safety inspection

- Hydraulic & pneumatic cylinders, and oil injector & ejector

- Pressure vessel that can hold people

- Tank lorry for vehicle

- Piping components used for the purpose of piping, flow measuring, or flow control.

-

Silencers or strainers (including filter), falling under any of the following categories.

- 1) No weld joint, with the exception of welds to attach a flange

- 2) Exterior diameter of the body is 320mm or less, and the nominal diameter of pipe joint is more than one-half of exterior diameter of the body

- A part of the machinery and equipment forms a pressured area such as body or head in a pressure vessel.

-

The product of working pressure (unit: MPa) and vessel inner volume (unit: m2) is less than 0.1, and the vessel falls under any of the following categories.

- 1) A component of machine & equipment

- 2) Attached equipment of pressure devices such as pump or compressor, for which the purpose of use is sealing, lubrication or heat exchange

(but, fluid if handled for relevant process must not be a dangerous substances regulated in Rules on Occupational Safety And Health Act [Attached table 1])

- Transport vessels to contain products for sales or supply

- Direct fired tube type process heater

- Sealed expansion tank for non-industrial use

- A component of machine & equipment subject to safety inspection

- A component of a small compressor (reciprocating compressor is fixed or attached on top of pressure vessel)

- Pressure vessels with a working pressure of less than 2fkg/cm2

Scope of vessel inspection

- For welding connection to an external pipe, the scope covers the first weld joint in the circumferential direction.

- For screw connection to an external pipe, the scope covers the first screw connection.

- For flange connection to an external pipe, the scope covers the first flange.

- If attachments are welded directly to the internal pressure part, the scope covers that weld joint.

- The scope includes pressurized covering plates for manhole or handhole, weld joint, bolts & nuts, and gaskets.

- ※ Fluid handling vessels in chemical processes are facilities used to store, separate, transport, and mix the fluid required for chemical processes such as evaporation, absorption, distillation, dry, and adhesion, referring to columns (distillation column, absorption column, extraction column, decompression column, etc.), reactors, mixing tanks, heat exchangers (heater, cooler, evaporator, condenser, etc.) filters, and storage vessels, and include vessels that handle dangerous substances as per the Rules on Occupational Safety And Health Act [Attached table 1].

Legal sanction Article 175 (4)-3 of The Occupational Safety And Health Act

Imposition of fine for negligence not exceeding 10 million won

Article 41 (2), Article 42 (1) (5) and (6), Article 44 (1) former part, Article 45 (2), Article 46 (1), Article 67 (1), Article 70 (2) latter part, Article 71 (3) latter part, Article 71 (4), Article 72 (1) (3) and (5) *Applicable to building construction contractor

A person who violates Article 77 (1), Article 78, Article 85 (1), Article 93 (1) former part, Article 95, Article 99 (2), main sentence, other than the part of the subparagraphs, of Article 107 (1).

Validity of an inspection

Article 126 (3) of the Enforcement Rule Of The Occupational Safety And Health Act

For pressure vessels, the first safety inspection shall be conducted within 3 years from the date of finishing installation in the workplace. After that, a safety inspection shall be conducted biennially. (Quadrennially for pressure vessels confirmed by submitting a process safety report.)